Driven by a change in the market environment of the precision tools industry – not least through the economic crisis in 2008/2009 – Schumacher has developed and implemented a new management tool: the comprehensive system ToolDesign This system features procedures for process control which are a world’s first in the context of industrial SME.

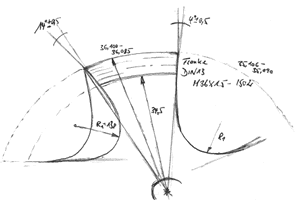

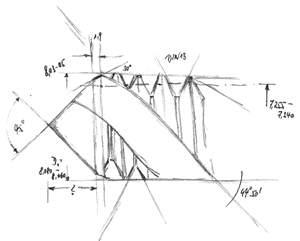

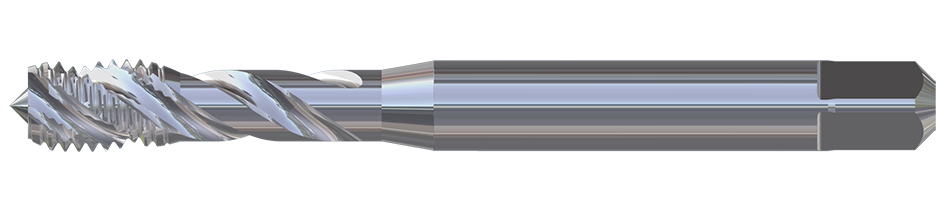

Amongst its functions as a comprehesive system, ToolDesign autimatically engineers and develops precision tools – mainly targeting taps, drills and end mills. These are tool groups with a very high complexity when it comes to the tool parameters required for the engineering (up to 190 different single data per tool).

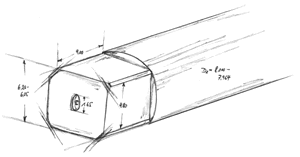

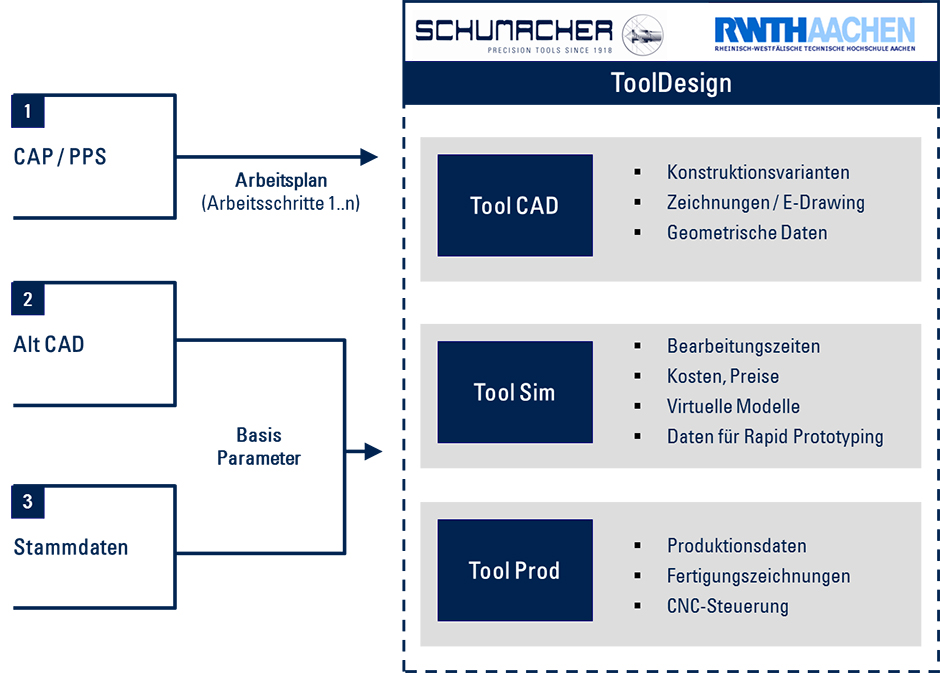

A detailed planning system serves as the base to ToolDesign – it has been used at Schumacher for the administration of any technology data and for the production-relevant CAD models since ten years.

Through an intelligent software system, ToolDesign generates the entire set of product data for new tool variants parallely provides the working parameters required for the production process on CNC turning-, milling- or grinding machinery.

This results in completely new sets of data for the production of new tool variants – which are mandatory for the geometry data of products in the same way as they are for the basis data of CNC control systems.

A data base system at Schumacher which stores the geometry data of some 35,000 product versions in a structured way, provides the required technology for the necessary linkages and design of new tools. A key component of ToolDesign is the data of more than five million single parameters, containing the technological know-how of Schumacher.

Through this procedure, tool producers have a method to handle the swiftly increasing efford in planning and designing precision tools in a very competitive environment. The comprehensive automation of the design process serves to meet the phenomenon of increasing demand for engineering services in the design process of new tool variants – which can only rarely be considered to the required extent in the sales price of the tool.