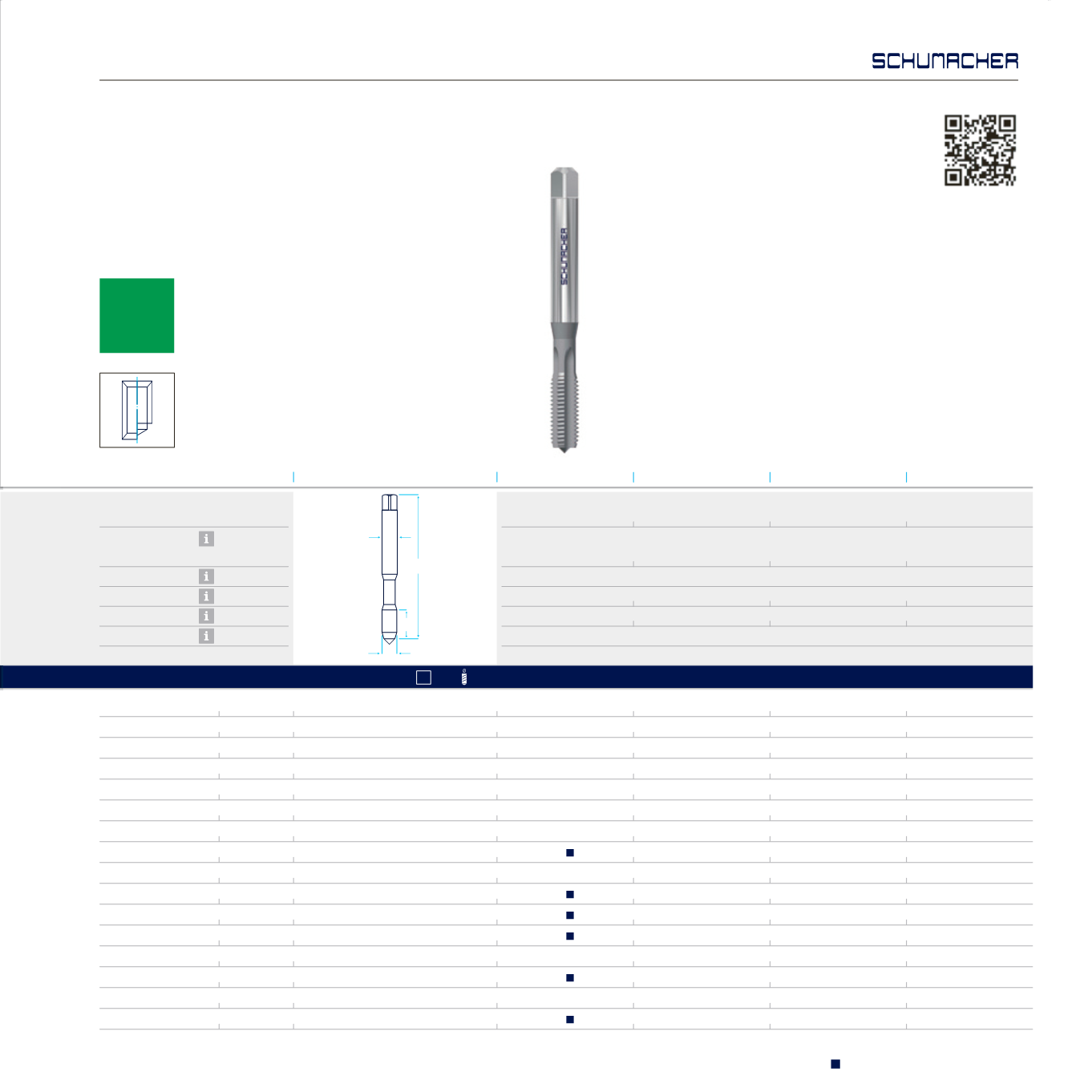

MS

Ø d

1

P

mm

L

1

L

2

d

2

Art.-No.

available – intermediate size on request

Technology

Chamfer Length

Surface

Tolerance

Cutting Data

Page 8.1

Page 8.2

Page 8.3

Page 8.4

Page 8.5

M 1.7

0.35

40 8 2.5 2.1 1.35

M 1.8

0.35

40 8 2.5 2.1 1.45

M 2

0.4

45 8 2.8 2.1 1.6

M 2.2

0.45

45 8 2.8 2.1 1.75

M 2.3

0.4

45 8 2.8 2.1 1.9

M 2.5

0.45

50 9 2.8 2.1 2.05

M 2.6

0.45

50 9 2.8 2.1 2.15

M 3

0.5

56 11 3.5 2.7 2.5

M 3.5

0.6

56 12 4

3

2.9

M 4

0.7

63 13 4.5 3.4 3.3

M 5

0.8

70 15 6

4.9 4.2

M 6

1

80 17 6

4.9 5.0

M 7

1

80 17 7

5.5 6.0

M 8

1.25

90 20 8

6.2 6.8

M 9

1.25

90 20 9

7

7.8

M 10

1.5

100 22 10 8

8.5

30200

E / 1.5-2 x P

bright

ISO2 (6H)

N3 copper alloys

L

1

d

1

L

2

d

2

2xd

1

Cutting Data

Machine Taps

DIN 371 HSS-E

straight flutes

for copper alloys

Group 3020

for blind and through holes

M - ISO Metric Coarse Thread DIN 13

2.5