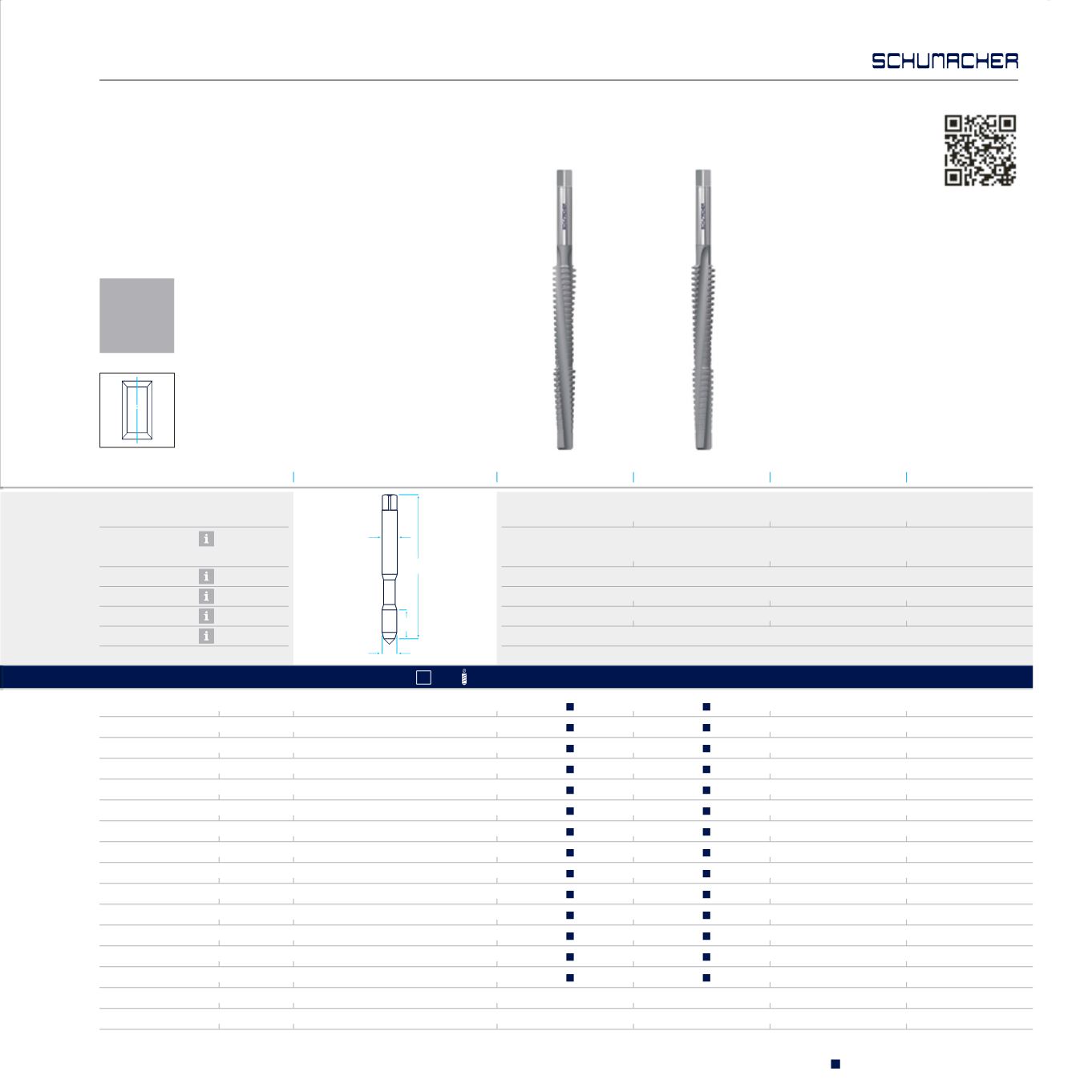

Ø d

1

P

mm

L

1

L

2

d

2

STEEL

Art.-No.

available – intermediate size on request

Technology

Chamfer Length

Surface

Tolerance

Cutting Data

Page 8.1

Page 8.2

Page 8.3

Page 8.4

Page 8.5

68500

bright

7H

P1 general construction steel K2+K3 spheroidal and malleable cast iron

LH

68505

bright

7H

Tr 10

2

110 65 7

5,5 8.2

Tr 12

3

160 110 8

6,2 9.25

Tr 14

3

160 110 10 8

11.25

Tr 16

4

200 130 11 9

12.3

Tr 18

4

200 130 12 9

14.3

Tr 20

4

200 130 15 12 16.3

Tr 22

5

240 155 16 12 17.3

Tr 24

5

240 155 18 14,5 19.3

Tr 26

5

260 165 20 16 21.3

Tr 28

5

270 170 22 18 23.3

Tr 30

6

290 190 22 18 24.3

Tr 32

6

300 190 25 20 26.3

Tr 36

6

320 200 28 22 30.3

Tr 40

7

390 250 32 24 33.5

L

1

d

1

L

2

d

2

2xd

1

Cutting Data

Single Finishing Machine Taps

internal standard HSS-E

2-step design, RH thread - LH spiral flutes 6°

LH thread - RH spiral flutes 6°, for general construction steel

Group 6850

for through holes

TR - ISO Metric Trapezoidal Thread DIN 103 1977

6.6