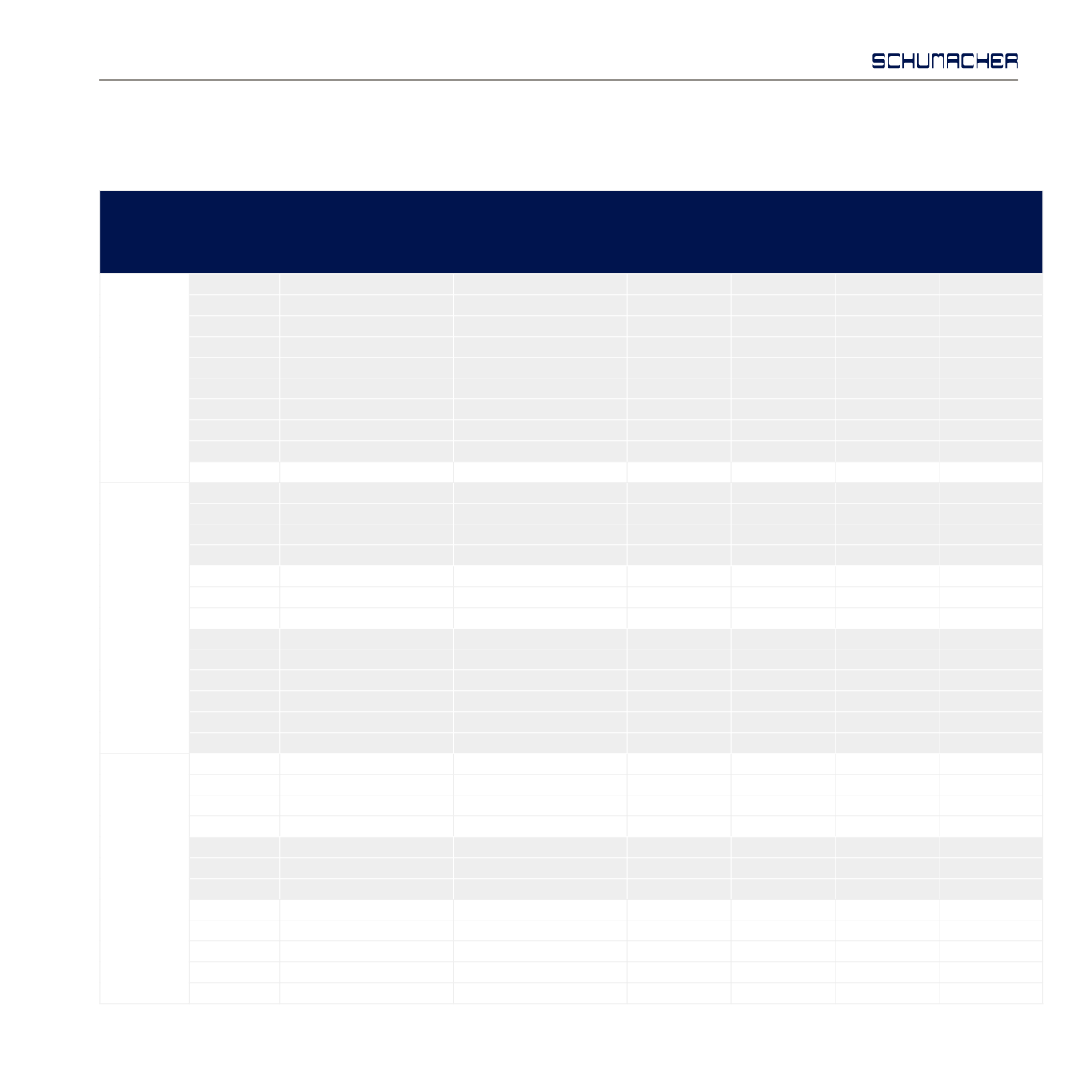

Technology

M

M1

Stainless steels ferritic

X 6 Cr 13

1.4000

400 - 600

3 - 5

5 - 8

M1

Stainless steels ferritic

X 4 CrMoS 18

1.4105

450 - 650

3 - 5

5 - 8

M1

Stainless steels martensitic X 30Cr 13

1.4028

800 - 1000

3 - 5

5 - 8

M1

Stainless steels martensitic X 12 CrMoS 17

1.4104

600 - 840

3 - 5

5 - 8

M1

Stainless steels austenitic

X 5 CrNi 18 10

1.4301

500 - 700

3 - 5

5 - 8

M1

Stainless steels austenitic

X 6 CrNiMoTi 17 12 2

1.4571

500 - 730

3 - 5

5 - 8

M1

Stainless steels austenitic

X 2 CrNiMo 18 14 3

1.4435

490 - 690

3 - 5

5 - 8

M1

Cast Steels

G X 6 CrNiMo 18 10

1.4408

440 - 640

3 - 5

5 - 8

M1

Cast Steels

G X 2 CrNiMoN 17 13 5

1.4439

490 - 690

3 - 5

5 - 8

M2

Duplex steels

X 2 CrNiMoN22-5-3

1.4462

880

3 - 5

5 - 8

K

K1

Grey cast iron

EN-GJL-100 (GG 10)

0.6010

88

8 - 12 |

25 - 30

12 - 20

K1

Grey cast iron

EN-GJL-200 (GG 20)

0.6020

195

8 - 12 |

25 - 30

12 - 20

K1

Grey cast iron

EN-GJL-300 (GG 30)

0.6030

295

8 - 12 |

25 - 30

12 - 20

K1

Grey cast iron

EN-GJL-400 (GG 40)

0.6040

390

8 - 12 |

25 - 30

12 - 20

K2

Nodular cast iron

EN-GJS-400-15 (GGG 40)

0.7040

400

5 - 8

10 - 20

K2

Nodular cast iron

EN-GJS-500-7 (GGG 50)

0.7045

500

5 - 8

10 - 20

K2

Nodular cast iron

EN-GJS-600-3 (GGG 60)

0.7060

600

5 - 8

10 - 20

K3

Malleable cast iron

EN-GJMW-400-5 (GTW-40)

0.8040

400

10 - 15

15 - 20

K3

Malleable cast iron

EN-GJMW-450-7 (GTW-45)

0.8045

450

10 - 15

15 - 20

K3

Malleable cast iron

EN-GJMW-550-4 (GTW-55)

0.8055

550

10 - 15

15 - 20

K3

Malleable cast iron

EN-GJMB-350-10 (GTS-35)

0.8135

350

10 - 15

15 - 20

K3

Malleable cast iron

EN-GJMB-450-6 (GTS-45)

0.8145

450

10 - 15

15 - 20

K3

Malleable cast iron

EN-GJMB-550-4 (GTS-55)

0.8155

550

10 - 15

15 - 20

N

N1

Aluminium wrought alloys

AlMn 1

3.0515

150 - 200

20 - 25

25 - 35

N1

Aluminium wrought alloys

AlMg 3

3.3535

200 - 300

20 - 25

25 - 35

N1

Aluminium wrought alloys

AlMgSiPb

3.0615

200 - 270

20 - 25

25 - 35

N1

Aluminium wrought alloys

AlZn 4.5 Mg 1

3.4335

20 - 25

25 - 35

N2

Aluminium cast alloys

G-Al Mg 3

3.3541

140 - 200

20 - 30

30 - 40

N2

Aluminium cast alloys

G-Al Cu 4

3.1841

280 - 400

20 - 30

30 - 40

N2

Aluminium cast alloys

G-Al Si 10 Mg

3.2381

250 - 320

20 - 30

30 - 40

N3

Copper alloys

E-Cu

2.0060

250

10 - 15

15 - 20

N3

Copper alloys

SE-Cu

2.0070

300

10 - 15

15 - 20

N3

Special copper alloys

Ampco 18

159 - 183

2 - 4

4 - 6

N3

Special copper alloys

Ampco 21

285 - 311

2 - 4

4 - 6

N3

Special copper alloys

Ampco 25

356 - 394

2 - 4

4 - 6

DIN ISO 513 I Schumacher

Material-No.

[N/mm2]

bright

I

coated

Cutting Speed v

c

[m/min]

v

c

forming taps = v

c

+ 30-50%

Material Groups

Description

DIN Description

DIN 17 007

Strength

HSS-E /

VHM

Work Piece Material Groups/Cutting Data

8.7